Torque testers are devices that measure and calibrate torque in tools, parts and equipment. They typically determine the maximum and minimum torque as well as the accuracy of the actual output as compared to the displayed amount. Read More…

We provide dynamometer test controls and equipment for a wide range of applications. Our test cell control system is compatible with all types of dynamometers, including AC & DC motoring dynos & Water Brake Systems. Our products all include the durability & quality customers expect from SAKOR. Our dynamometers are powerful & affordable for the automotive, aerospace & heavy equipment industries.

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

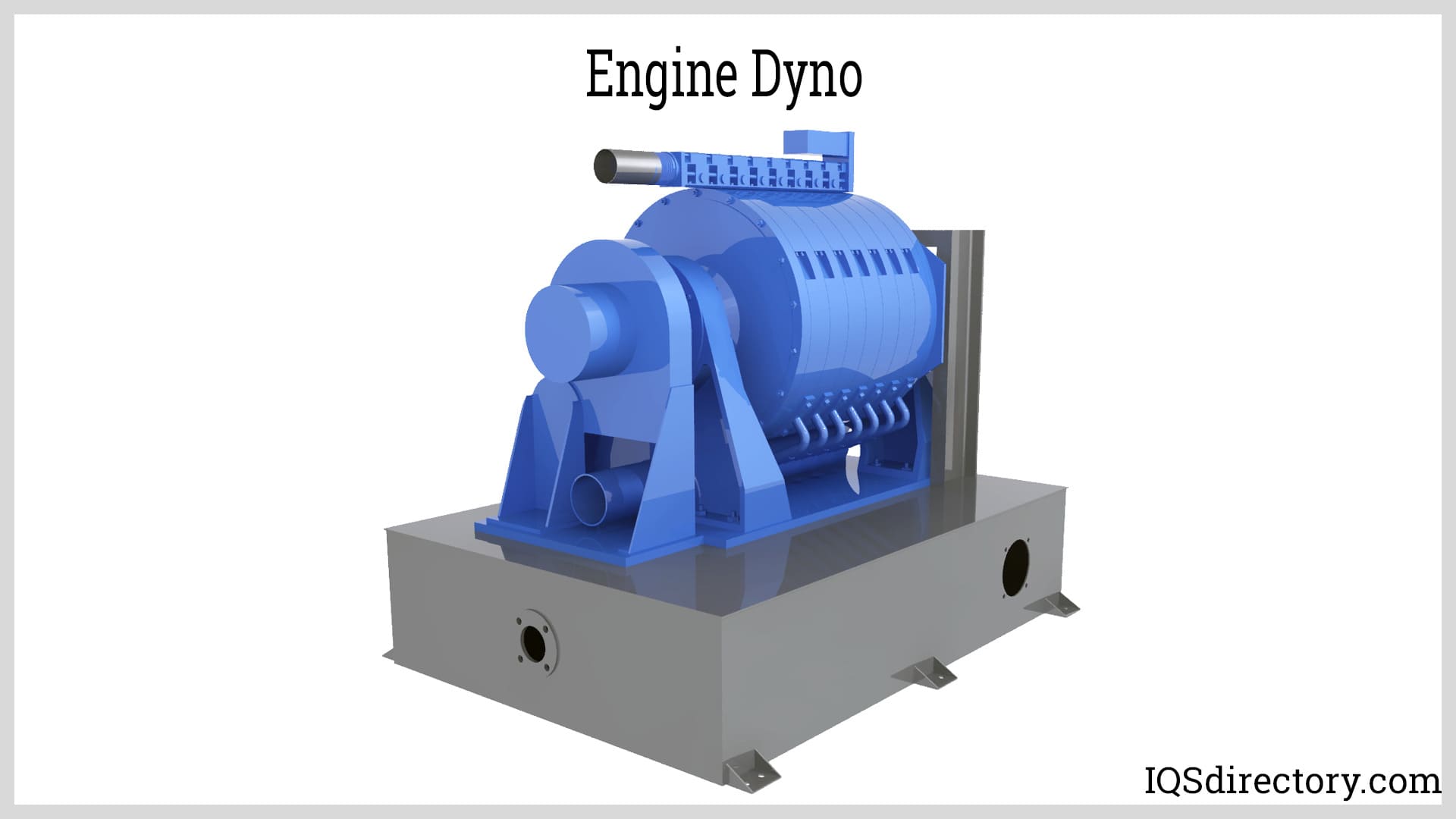

For over 45 years, Mustang Dynamometers has been a worldwide manufacturer and designer of the highest quality, most accurate testing equipment such as chassis dynamometers, engine dynos and transmission dynes systems in the world. Our sister company, Mustang Advanced Engineering, has created world leading solutions for testing. Visit MustangDyne.com for more information. Follow them on Facebook,...

When accuracy, reliability and performance matter look to the name that means dependability: A&D Technology. If you’re looking for an AC Dynamometer or an EC Dynamometer, A&D has you covered! We are a leader in dynamometers and have extensive advantages over other dynamometer manufacturers. Contact us today for more information!

More Torque Tester Manufacturers

Though similar in purpose, they are different from dynos. Some have a temperature compensation feature that prevents a mistaken reading by accounting for the effect increasing or decreasing temperatures can have on a measurement.

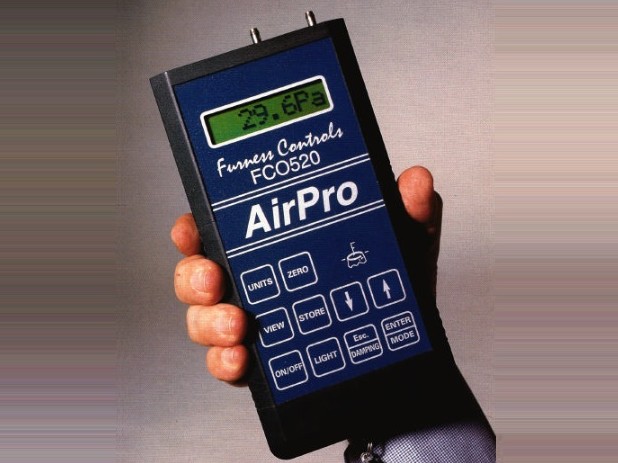

Modern torque testers are able to measure torque in clockwise and counterclockwise directions as well as convert the reading into a number of units. Common outputs and arrangements for these devices include analog voltage, analog current, modulated frequency, switch or alarm, serial and parallel.

In addition, some are designed for use in difficult environments and have increased resistance to shock and vibration in order to take an accurate and fast reading. Many torque testers are handheld electronic devices with a small screen to display the readings.

The components are encased in plastic and several input buttons allow the user to select the preferred options. Torque testers are an important device that maintains safe and efficient conditions. They measure and calibrate tools such as torque wrenches and electric screwdrivers as well as machines and industrial equipment like automotive engines and centrifugal pumps.

Torque testers have three main components. A transducer, or load cell, is a device that converts force into an electrical signal. There are three main ways of doing this. Magnetoelectric sensors use any detected changes in their own magnetic field to create a signal, which is different from eddy current dynamometers, though both use magnets to measure torque.

Piezoelectric sensors are compressed by the force of the torque, thus generating a charge. A strain gauge becomes deformed when the force from the torque travels through an assembly and distorts it; the distortion is then converted into electric signals and amplified.

There are two main kinds of sensors that testers use: reaction and rotary. Reaction torque testers use a stationary transducer while rotary testers use a rotating transducer to take readings. After an algorithm calculates the force applied to the transducer that produced a current of that magnitude, the results are displayed on a screen.

The display and transducer may be held in the same housing or an external transducer can be connected to a portable display. During calibration, a joint simulator, or rundown fixture, is used to test power tools. The joint simulator is placed on top of the transducers with an adapter bit to attach the two. Springs or washers are used to simulate how a tool would behave while operating in a normal setting.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services