Dynamometers, also known as dynomometers, dynometers, dynos and, within context, electric motor testers/motor testers, are devices that measure and test: force, tension force, horsepower and torque, maximum rotary speed or maximum power absorption. They are not to be confused with torque testers, dynamos or dynameters. Read More…

We provide dynamometer test controls and equipment for a wide range of applications. Our test cell control system is compatible with all types of dynamometers, including AC & DC motoring dynos & Water Brake Systems. Our products all include the durability & quality customers expect from SAKOR. Our dynamometers are powerful & affordable for the automotive, aerospace & heavy equipment industries.

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, and industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

More Dynamometers Manufacturers

The term “dynamometer” can initially seem complex. To simplify, it derives from Latin roots: “dynamo” meaning “force, energy, or power,” and “meter” meaning “instrument for measurement.”

Applications of Dynamometers

Dynamometer systems are primarily used to test and measure the forces generated by engines. They are commonly applied in various fields, including RPM and torque measurement of chain or belt drives, fluid power systems, diesel or gas systems, gearboxes, and turbines. These systems are essential in the measurement of engines used in aircraft, aerospace, marine, automotive, and industrial processes.

History of Dynamometers

Dynamometers have been utilized since the 18th century for measuring horsepower and torque. Engineers continuously innovated and refined these devices from the early 1700s to the mid-1900s. One of the earliest examples, the Graham-Desaguliers Dynamometer, was developed by George Graham, a British clockmaker and geophysicist, and later improved by John Desaguliers, who documented it in 1719. In 1798, French engineer Edme Régnier introduced the Regnier dynamometer.

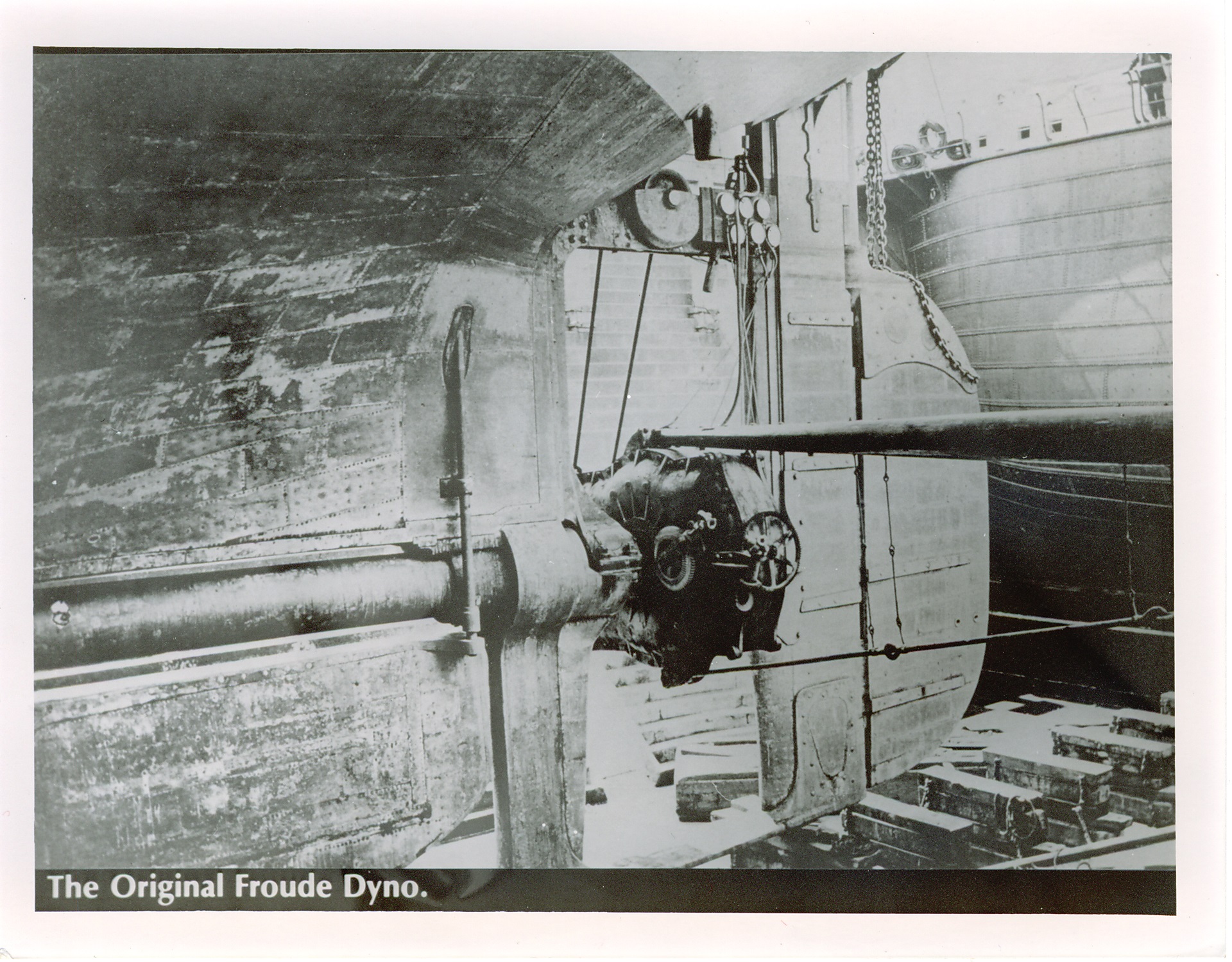

Notable 19th-century dynamometer inventions include the improved weight machine patented by Siebe and Marriot in 1817, the de Prony brake by Gaspard de Prony in 1821, Macneil’s road indicator by John Macneil in the late 1820s, and the hydraulic dynamometer by William Froude in 1877. The first commercial dynamometers were produced in 1881 by Heenan & Froude, which remains active today as Froude, Inc. and Froude, Ltd.

In the early to mid-20th century, dynamometers advanced significantly for vehicle engines and motor power. Carl Schenck Eisengießerei & Waagenfabrik developed the first brake testing vehicle dynos in 1928. DC motor dynos were also used during this period. In 1931, Martin and Anthony Winther invented the eddy current dynamometer for trains and train brake power.

Modern dynamometers, benefiting from improved machining, design, materials, and technology, are now highly complex and come in various shapes and sizes to meet specific needs.

How Dynamometers Work

Dynamometers utilize various devices for testing and measurement. For instance, some dynamometers incorporate transducers, strain gauges, and display screens to convert torque into an electrical signal, which is then amplified, converted, and displayed. Other dynamometers employ motor testers, which use voltage and current probes attached to motor input wires, connecting to internal voltmeters, ammeters, and ohmmeters. These testers measure direction, torque, voltage, power, current, cut-out speed, and efficiency. Additionally, non-contact speed sensors are used to measure motor drive shaft speed, determining the number of rotations per minute.

Types of Dynamometers

There are two main types of dynamometers commonly used in the automotive and manufacturing industries: chassis dynamometers and engine dynamometers.

Chassis dynamometers measure wheel rotation to determine engine or motor torque using computer software. These devices are stationary rollers on which vehicle wheels are placed for measurement. Chassis dynamometers include subsets like inertia dynamometers and hydraulic dynamometers.

Inertia dynamometers are ideal for continuous runs. They use electric motors to turn a flywheel mass, roughly one-quarter the weight of the test vehicle. When the flywheel mass reaches the designated RPM (revolutions per minute), the dynamometer applies and measures braking forces.

Hydraulic dynamometers measure engine or motor power using a casing filled with hydraulic fluid to increase load. They comprise a fluid reservoir, a hydraulic pump, and piping with an adjustable valve. Measurement is achieved via a strain gauge or load cell positioned between the pump and the valves. These dynamometers offer the fastest load change capability.

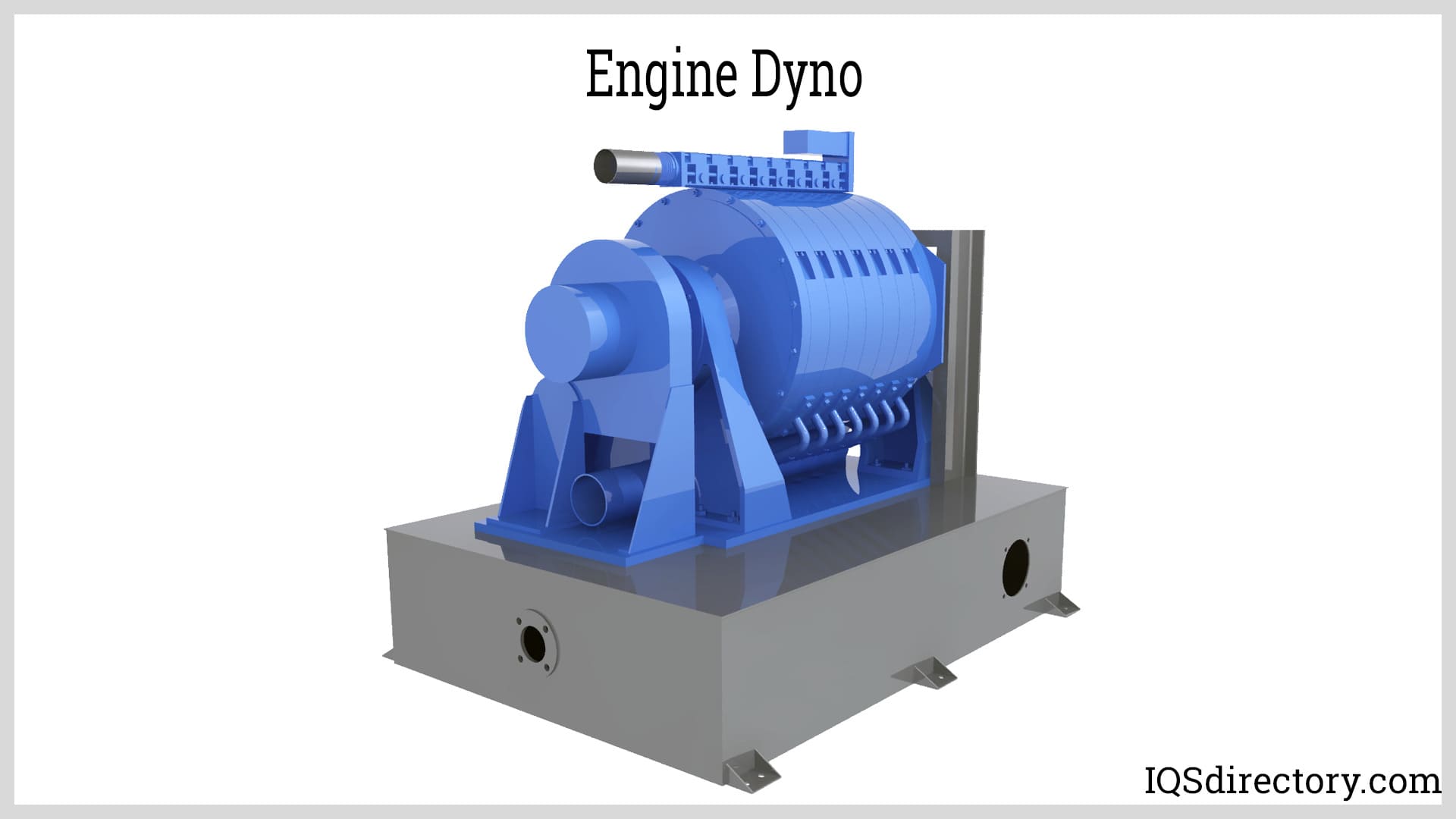

Engine dynamometers measure power directly from the engine with minimal computer intervention, utilizing analogue gauges and dials while final calculations are computerized. They provide highly accurate and repeatable results. Engine dynamometers are popular among engine rebuilders, auto manufacturers, and producers of race cars and high-performance vehicles, as they require the engine or motor to be removed from the vehicle for testing. Their subsets include brake dynamometers, eddy current dynamometers, PTO dynamometers, certain hydraulic dynamometers, and spring dynamometers.

Brake dynamometers operate by measuring the engine’s response to varying loads, where a braking force is applied to slow down the engine. This intricate process provides valuable insights into the engine’s performance under different conditions.

Eddy current dynamometers, a specific type of brake dynamometer, work by generating a circulating electron flow. This flow creates a repelling or dragging force between a conductor and a changing magnetic field, offering precise control over the braking force and enabling accurate measurements of engine response.

PTO dynamometers, also known as power take-off dynamometers, are designed to transfer power from an external drive, typically found on tractors or trucks, to an attached machine. By using eddy current technology, PTO dynamometers measure torque with high accuracy, making them indispensable in agricultural and industrial applications where precise power measurement is crucial.

Spring dynamometers are elegantly simple in design, consisting of a metal spring and a two-part mounting surface. When attached to the load being measured, the spring dynamometer measures force through the deformation of the spring, providing a straightforward yet effective method for gauging force. This simplicity makes them versatile and easy to use in various measurement scenarios.

Components of Dynamometers

Dynos, despite their diversity in design, typically include several fundamental components: an absorption unit or driver, a system for producing torque, and an apparatus for measuring both torque and rotational speed. The absorber is generally a rotor enclosed in a housing, linked to the equipment being tested. Torque is usually generated through friction, hydraulic fluid, or electromagnetic energy. Measurement devices commonly consist of load cells or strain gauges, though other types of scales, such as crane scales, might also be employed. Load cells, also referred to as load sensors, transform mechanical force into quantifiable electrical signals, facilitating accurate force measurement.

How to Use Dynamometers

The procedure for using a test dynamometer depends on the specific tests to be conducted. Generally, engineers should start by setting the control panel to either Load Control or Speed Control, enabling the measurement of load or speed.

Once the control mode is set, ensure the throttle is fully open and Speed Control mode is activated. Begin by powering the engine at a low speed, then gradually increase it to take performance measurements. This process can be repeated as needed to determine or reach the optimal speed.

Before taking force or power measurements, ensure that engine cooling mechanisms, such as fans, are properly set up to prevent overheating and related issues. Additionally, monitoring the temperature during operation can help reduce inaccuracies and errors.

Benefits of Dynamometers

Dynamometers provide significant benefits for manufacturers, enabling them to assess engine and electric motor power before market release. By identifying inefficiencies or performance issues such as slow acceleration or faulty brakes, manufacturers can make necessary adjustments to ensure optimal performance and safety. This proactive approach reduces the risk of costly repairs or recalls and enhances product reliability, assuring customers of the product’s safety.

Furthermore, dynamometers contribute to environmental health by promoting more efficient engine operation, resulting in reduced fuel consumption and emissions. They assist manufacturers in testing engines against EPA emissions standards. As dynamometers become increasingly advanced and automated, the reduction in human error leads to faster and more accurate measurements, ensuring ongoing improvements in engine safety, power, efficiency, and performance.

Designing Dynamometers

When designing a dynamometer, manufacturers take into account various factors, such as customer budget, testing application, and available space. To better meet your specific requirements, they can customize their products by adjusting the size to fit your space, creating special casings or mounts, selecting appropriate scale types, and incorporating other necessary features.

Depending on your application, your dynamometer may need to comply with various standards, such as those from SAE International and ASTM. SAE provides guidelines for chassis, inertia, and brake dynamometers, while ASTM offers standardized testing methods. To determine the necessary standards for your dynamometer, consult with industry leaders and relevant governmental offices.

Choosing the Right Dynamometer Manufacturer

To acquire a reliable and compliant dynamometer testing system, it is essential to collaborate with atrustworthy supplier. We recommend exploring the dynamometer manufacturers listed on this page, each of whom has consistently demonstrated their reliability.

While all these manufacturers are commendable, only one will be the perfect fit for your needs. To determine which, begin by comparing their services and products with your specific application. Select three or four companies and reach out to each for a conversation or quote. During these discussions, address key aspects such as budget, lead times, delivery preferences, custom options, and standard requirements. After evaluating their responses and customer service, choose the manufacturer that best aligns with your needs. Contact them to initiate the process.

Check out our Thermocouples website

Check out our Environmental Test Chambers website

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services