They are stable and take measurements without requiring the removal of the engine. These machines are also called water brake dynamometers because they use water or oil in the load cell. Read More…

We provide dynamometer test controls and equipment for a wide range of applications. Our test cell control system is compatible with all types of dynamometers, including AC & DC motoring dynos & Water Brake Systems. Our products all include the durability & quality customers expect from SAKOR. Our dynamometers are powerful & affordable for the automotive, aerospace & heavy equipment industries.

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, and industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

More Hydraulic Dynamometer Manufacturers

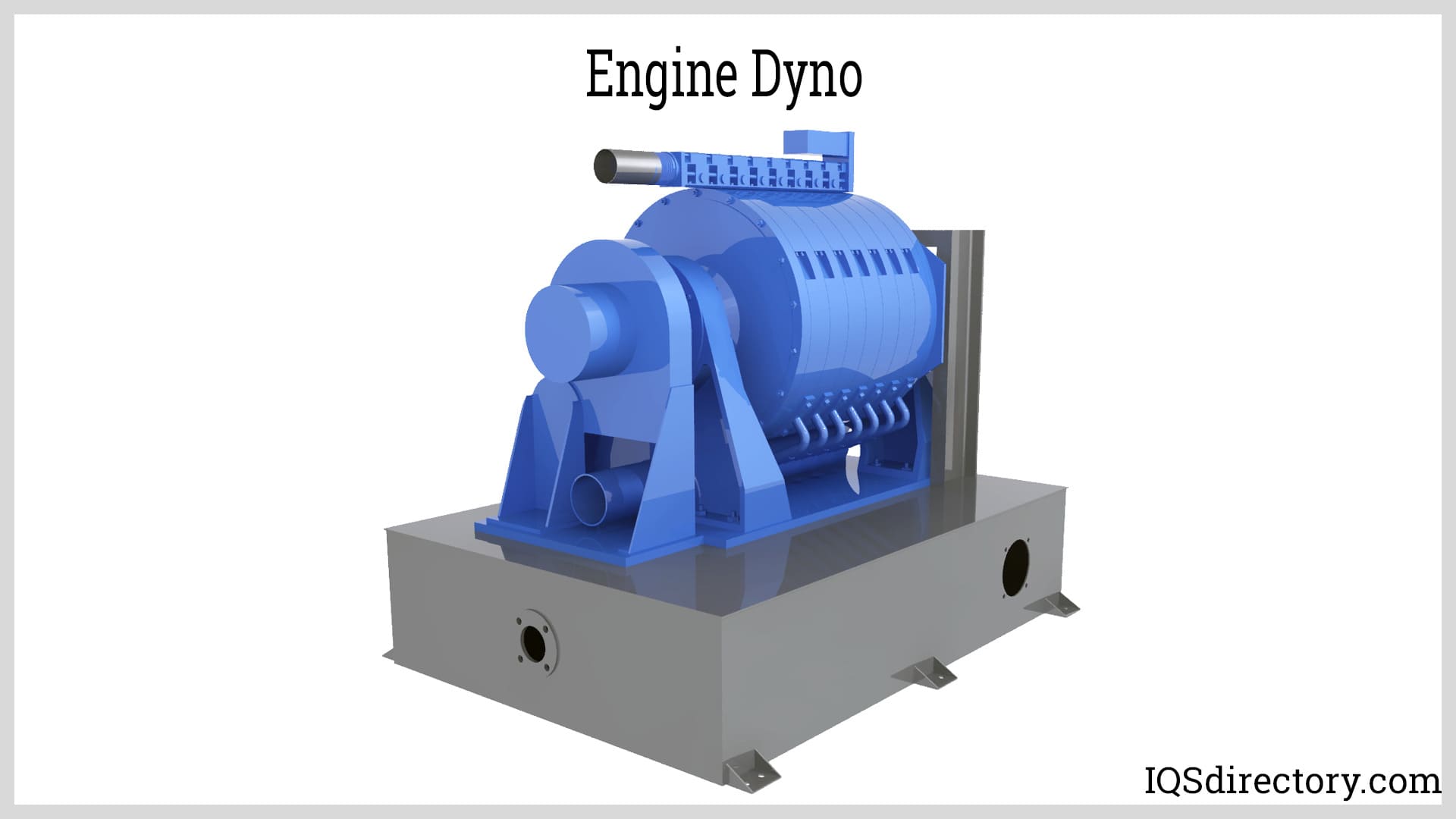

They can create different loads on the engine and maintain a steady RPM rate while testing. Because of this, they are often used for trouble shooting tuning problems in the engine and determining if a part is not performing. The working compartment of the hydraulic dynamometer consists of special semi-circular shaped vanes cast into stainless steel rotor and stators. Water flowing in a torodial vortex pattern around these vanes creates a torque reaction through the dynamometer casing which is measured by a precision load cell.

The hydraulic dynamometer fill level and consequently load is controlled by a water outlet valve, operated by a closed loop electro-hydraulic dynamometer fill level and consequently load is controlled by a water outlet valve, operated by a closed loop electro-hydraulic servo system.

The power absorbed by the dynamometer is carried away by the water in the form of heat. Applied torque by the dynamometer is measured by a load cell installed on the arm of the dynamometer. The load cell signal is transmitted to a load cell amplifier. Control command is supplied to the outlet analog water valve, through an electronic/pneumatic transducer, which converts the electric signal to proportional air quantity as supply to the valve.

Hydraulic dynamometers are used as loading units in engine test rigs. They cover a wide range of dynamometer power and torque values. They are well suited for testing of passenger car and commercial vehicle diesel engines, testing of large railway- and marine engines, engine testing in tandem configuration with asynchronous motor, testing in research and development testing in production and quality assurance.

They are however more complicated than systems that use rolling barrels because of the way the dynamometer is attached. Also, the data requires more effort and knowledge to decipher because most hydraulic dynamometers are analog.

These machines are used in automotive, aircraft, aerospace, marine, and industrial processes to measure chain or belt drives, gear boxes, fluid power systems, gas or diesel systems or transmissions in vehicles and motorcycles.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services