Automotive facilities utilize a brake tester to assess the condition of a stationary vehicle’s brake system. This evaluation assesses the brake’s performance and minimizes the dangers that can come from a vehicle having a faulty brake system. Brake testers might just be able to spare a vehicle from disaster. Read More…

We provide dynamometer test controls and equipment for a wide range of applications. Our test cell control system is compatible with all types of dynamometers, including AC & DC motoring dynos & Water Brake Systems. Our products all include the durability & quality customers expect from SAKOR. Our dynamometers are powerful & affordable for the automotive, aerospace & heavy equipment industries.

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, and industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

More Brake Testers Manufacturers

How a Brake Tester Works

The vehicle moves onto the brake tester, and its wheels are put between the two big main rollers. The specifications about the vehicle are entered, and the rollers automatically start spinning at a certain speed. Following this, brakes are applied, applying force onto the motor.

While the vehicle is motionless while being tested by the rollers, its total braking force is determined by the brake tester mechanism. The vehicle’s braking efficiency is then calculated by the tester mechanism’s automated weighing system.

Types of Brake Testers

There are at most three types of brake testers used to determine the braking effort and efficiency of a motor vehicle:

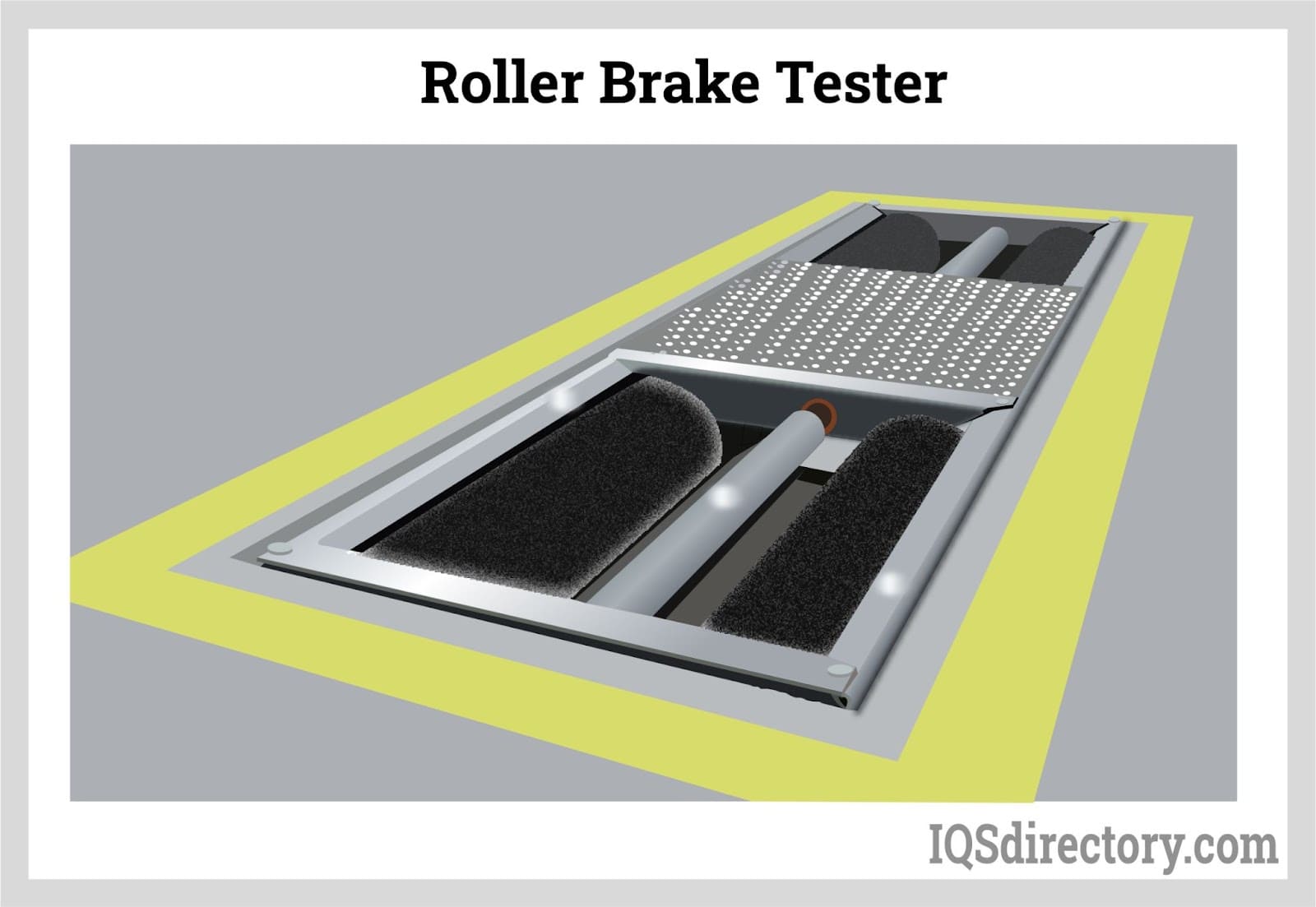

Roller Brake Tester

This is a way of permitting the dynamic evaluation of a motor vehicle’s braking system while the motor vehicle itself remains stationary.

A roller brake tester consists of a mechanical floor unit that comprises electrical motors, double independent sets of three measuring rollers, braking force transducers, and extra safety sensors.

The driving rollers function at a low speed using a motor and gearbox setup. During a test, the maximum braking force is measured by applying the vehicle’s brakes, inducing a reactive force on the electric motor.

An electric transducer coupled with strain gauges then determines the induced individual forces that are acting on the deceleration stage in order to calculate the separate braking forces on each wheel.

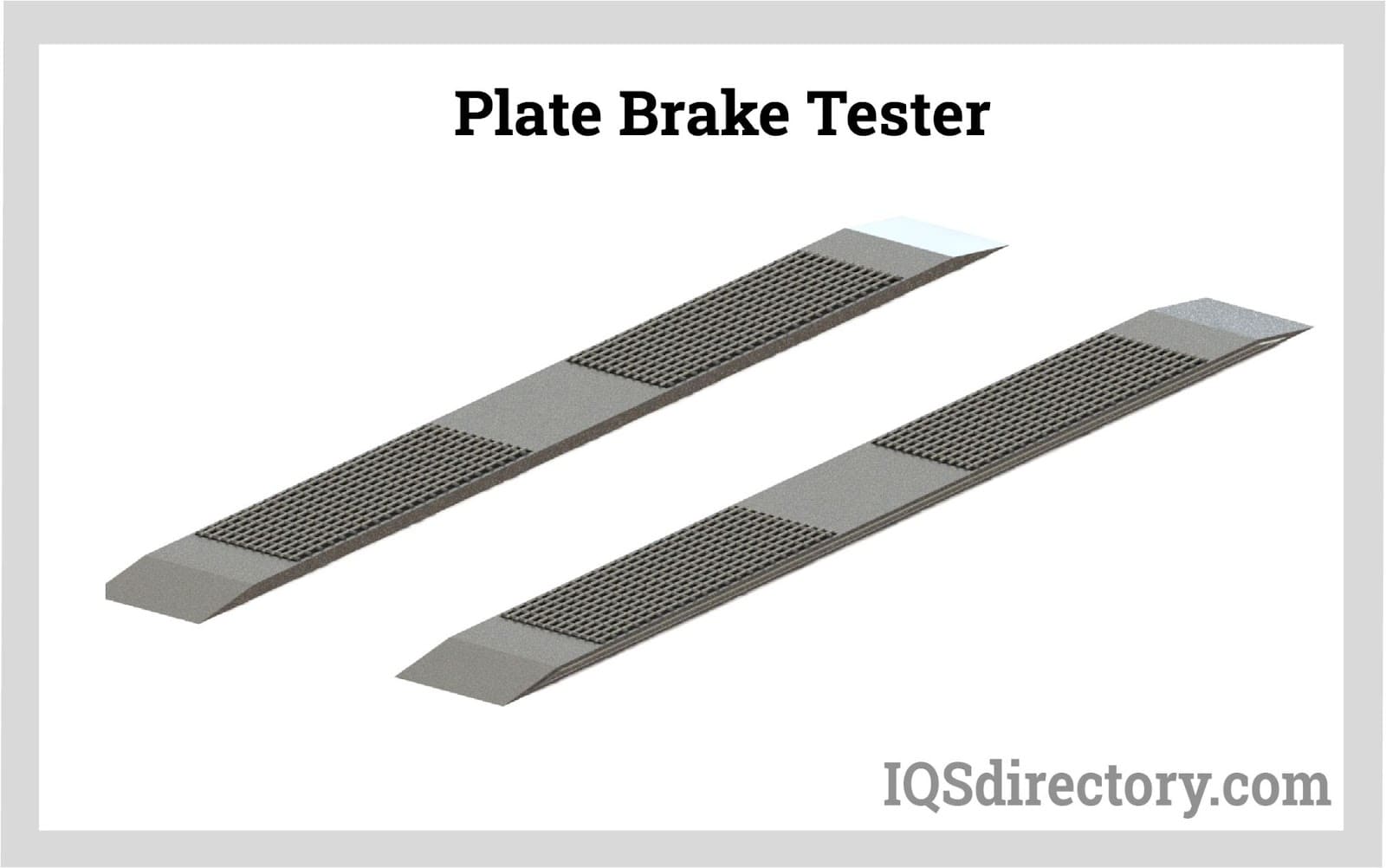

Plater Brake Tester

This is a method of determining a vehicle braking system during a dynamic test. The unit comprises 2 moving parallel plates fixed on force transducers. Braking force measurement is done when a vehicle moves over the plates and applies its brakes.

This braking action results in individual plates ‘slipping’ forwards, enabling the calculation of braking force. Brake imbalance between the right and left hand sides can also be determined by the variances in voltage measured on each individual force transducer below the chassis.

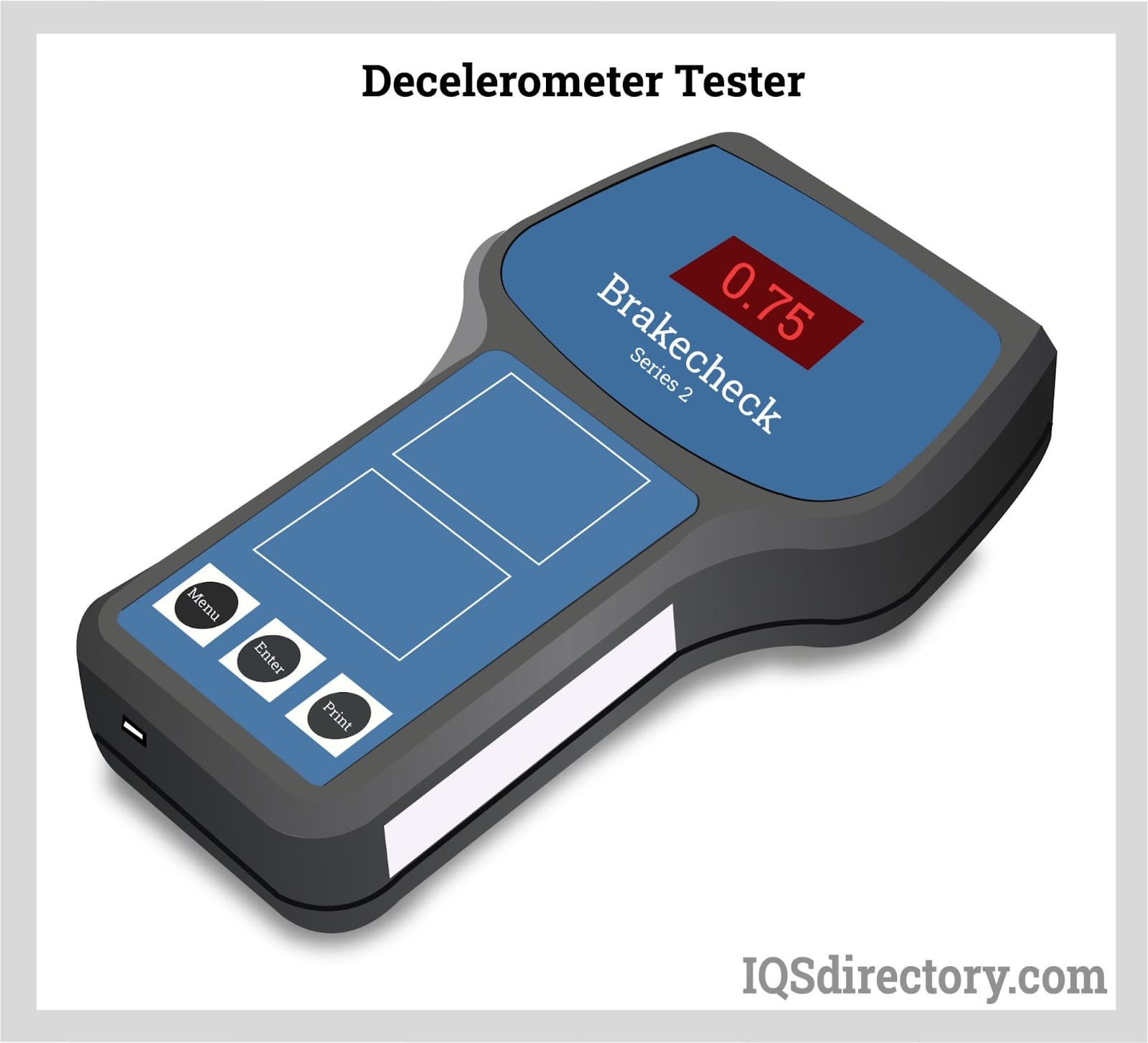

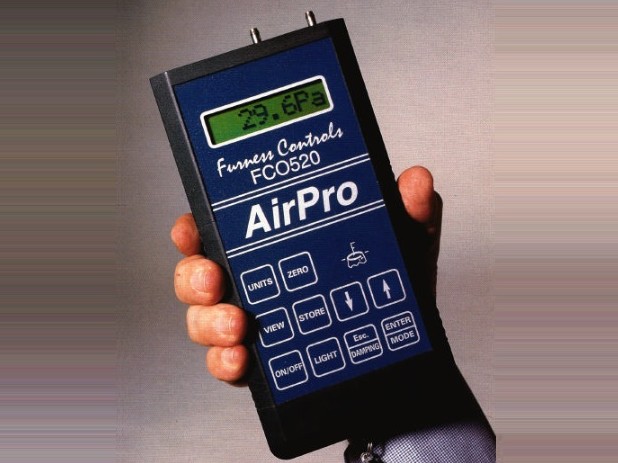

Decelerometer

This is a handheld tool for measuring the dynamic braking forces during the course of a vehicle road test. A vehicle decelerometer functions as if it were an accelerometer, as it determines braking efficiency by utilizing those forces measured during a vehicle's deceleration.

A decelerometer is a straightforward process by which braking effort may be accessed swiftly and easily, but it is normally utilized as an indicator of tolerable brake performance.

Low efficiency readings mast lead to more investigation on either a roller brake tester or a plate brake tester.

Considerations When Choosing Brake Testers

The considerations when selecting brake testers include:

Method of Operation

- Roller brake testers measure the force reaction created by the brakes against a roller rotated by a motor, while a plate brake tester has strain gauges fixed to a plate held on bearings, and it measures the force needed to hold the plate while a vehicle brakes on top of it.

- Decelerometers are put in a vehicle and feature a pendulum which moves if a vehicle is braked.

- The amount of pendulum ‘swinging’ is determined to show deceleration during braking.

Brake Test Safety

- Roller brake testing is a moderately safe testing method, since the vehicle is static during the brake test. Instead, the rollers spin underneath the wheels.

- With both the decelerometer and the plate brake tester, testing requires that the vehicle be driven and braked on the plates, usually in the limited space of a roadside or vehicle workshop.

- This can be a danger to other workshops or road users.

Accuracy of Results

- Roller brake testers utilize the same braking surfaces when testing all wheels on all vehicles, guaranteeing accurate comparative tests.

- Plate brake testers utilize the same braking surface for all the wheels on every vehicle, while the decelerometers tests on road; therefore, the braking surface could differ from very good to very bad based on road condition.

- While a roller brake tester tests all vehicles at a constant speed, the plate brake testers and decelerometers tend to brake test at variable test speeds based on how a vehicle is driven.

Brake Test Adaptability

- Roller brake testers are able to test the complete range of every brake applied on a vehicle, from zero to maximum braking, or wheel lock constantly and repeatedly without influence of weight or momentum transfer.

- The decelerometers and plate brake testers cannot test the complete range of a vehicle’s brake successfully.

- Decelerometers cannot test separate axles, while plate brake testers are able to compare the brake balance across separate axles. Roller brake testers can consistently and repeatedly make a comparison of the brake balance across individual axles.

Advantages of Brake Testers

Below are some of the advantages of the individual testers:

- Being quite affordable and fairly portable, the decelerometer enables ease of use in many environments.

- Plate testers have less moving pieces and offer a more in-depth test, enabling weighing of vehicle axles.

- Roller brake testers can be set up for air pressure testing, bind (rolling resistance), and ovality (cracked or warped discs/drums).

Choosing the Correct Brake Tester Supplier

For the most positive outcome when purchasing brake testers from a brake tester supplier, it is important to compare several companies using our directory of brake tester suppliers. Each brake tester supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or request a quote. Review each brake tester business website using our proprietary website previewer for a better understanding of what each company specializes in. Then use our simple RFQ form to contact multiple businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

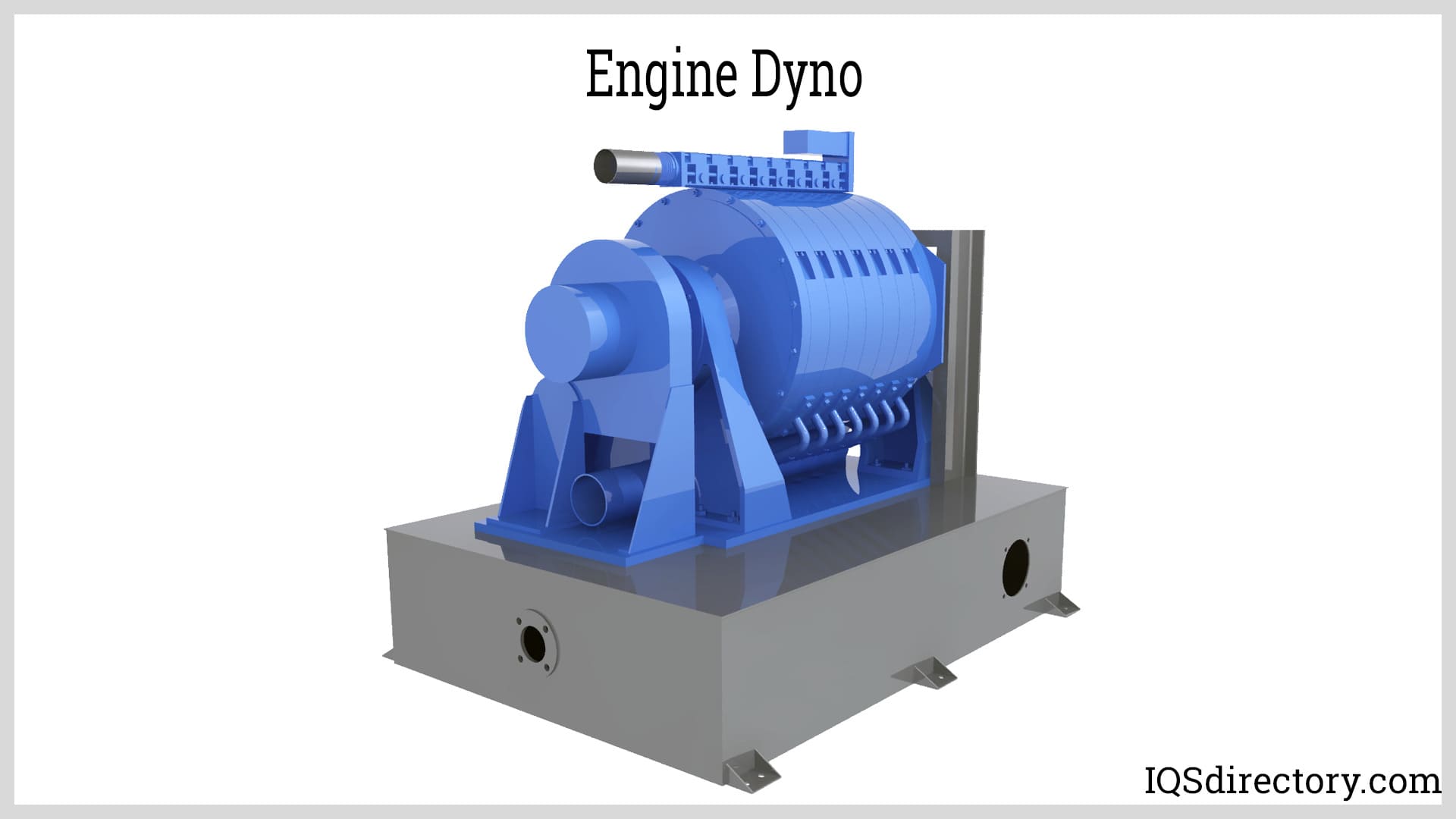

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services