PTO dynamometers are engineered and designed to meet the need for reliable PTO testing. PTO, or power take off, is a driveshaft used in industrial and agricultural sectors to provide power to a secondary or separate machine. Read More…

We provide dynamometer test controls and equipment for a wide range of applications. Our test cell control system is compatible with all types of dynamometers, including AC & DC motoring dynos & Water Brake Systems. Our products all include the durability & quality customers expect from SAKOR. Our dynamometers are powerful & affordable for the automotive, aerospace & heavy equipment industries.

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, and industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

More PTO Dynamometer Manufacturers

The PTO is on an engine usually located in a truck or a tractor that is then able to power an attached machine.

A PTO is produced according to a standardized basis for dimensions and speed, and the ISO standard for power take offs is ISO 500. Therefore, testing of the PTO is important, especially in agricultural settings where the equipment is crucial to the daily undertakings of the operation.

Accurate PTO testing provides information that can be used to lower machine maintenance costs and to improve the reliability of the equipment. Dynometers are devices used to measure force or power of an engine, motor or machine in terms of torque and revolutions per minute.

They can be used to determine horsepower, maximum rotary speed and maximum power absorption. An engine or machine is put under test, and the results of its performance are gathered by the dynamometer's data-acquisition electronic system. Dynamometers typically have feedback features for both speed and power for the purposes of performance testing and monitoring.

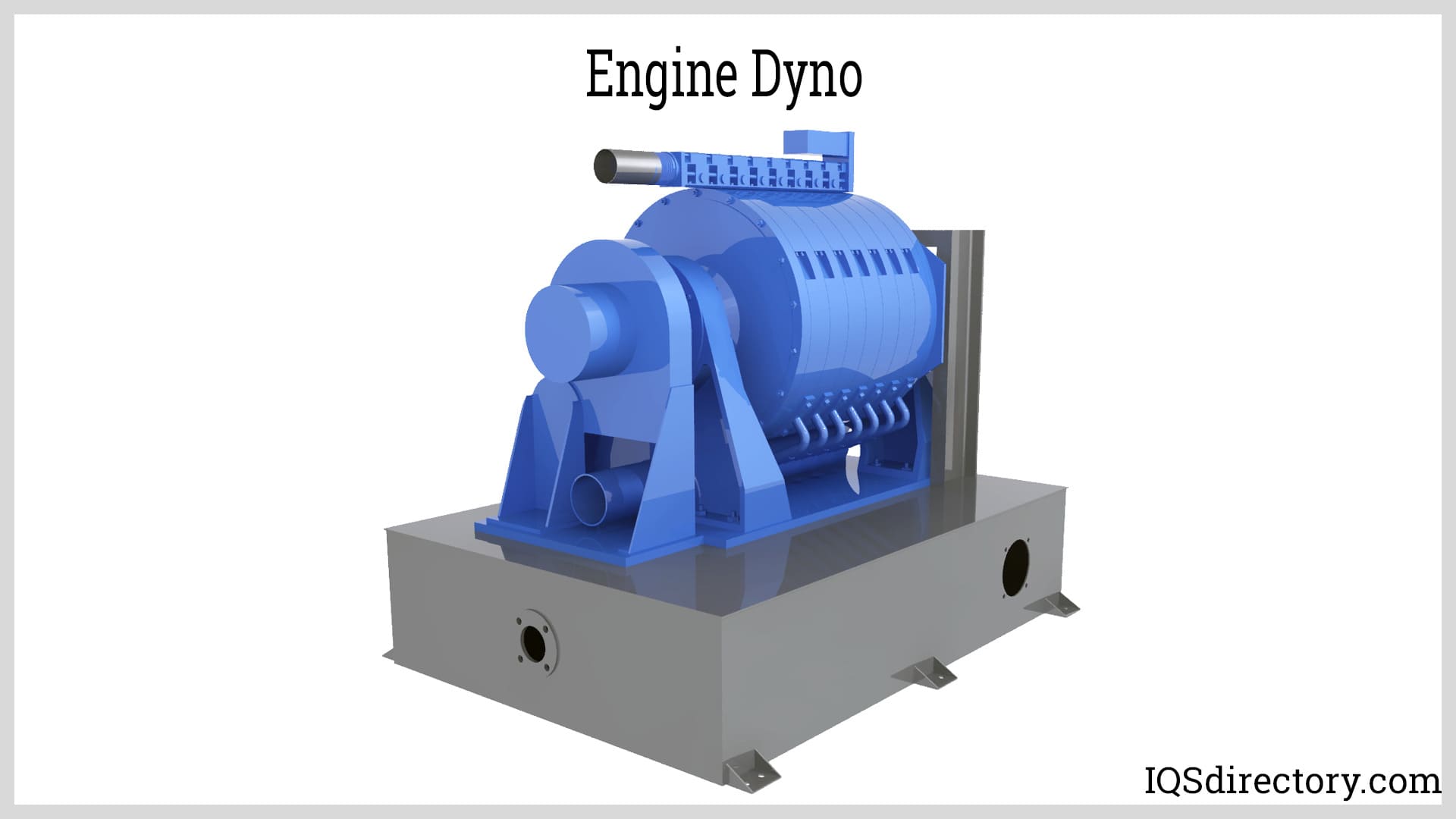

Most dynamometers, or dynos, are constructed of basic components including a frame, engine mounts, an absorption unit, a heat exchanger and a torque measuring device. Other common features that vary according to the specific application of the dynamometer include sensors, torque arms, flow control or throttling, alarms and encoders.

A computer system with a control console, or separate console, is responsible for acquiring data and analyzing motor power and capacity. This data is then able to be printed out, usually in graphs, and steps can be taken to improve the performance of the PTO according to areas of lost energy etc.

Power take off shafts have been responsible for a number of serious accidents and therefore caution should be used around them. They are designed to be easily connected and disconnected for ease of access to the source of power, but this allows open access to a powerful machine, which can be dangerous. Many are controlled by a push button or selector switch in an attempt to improve operator safety.

A dynamometer is typically an expensive piece of equipment and therefore is used in specified fields by qualified personnel.

Other common types of dynos include: brake dynamometers, chassis dynamometers, engine dynamometers and eddy current dynamometers.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services