An eddy current dynamometer is an electro-mechanical energy conversion machine that changes mechanical energy to electrical energy. It utilizes Faraday’s Law of electromagnetic induction as a working principle. Read More…

We provide dynamometer test controls and equipment for a wide range of applications. Our test cell control system is compatible with all types of dynamometers, including AC & DC motoring dynos & Water Brake Systems. Our products all include the durability & quality customers expect from SAKOR. Our dynamometers are powerful & affordable for the automotive, aerospace & heavy equipment industries.

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

Since our inception we have been committed to manufacturing top of the line dynamometers that will stand up to the rigorous wear and tear of every day application. Our products serve in many diverse industries including automotive, automation, and industrial as well as a broad variety of others! To learn more about what we may be able to do for you visit our website today for more information!

More Eddy Current Dynamometer Manufacturers

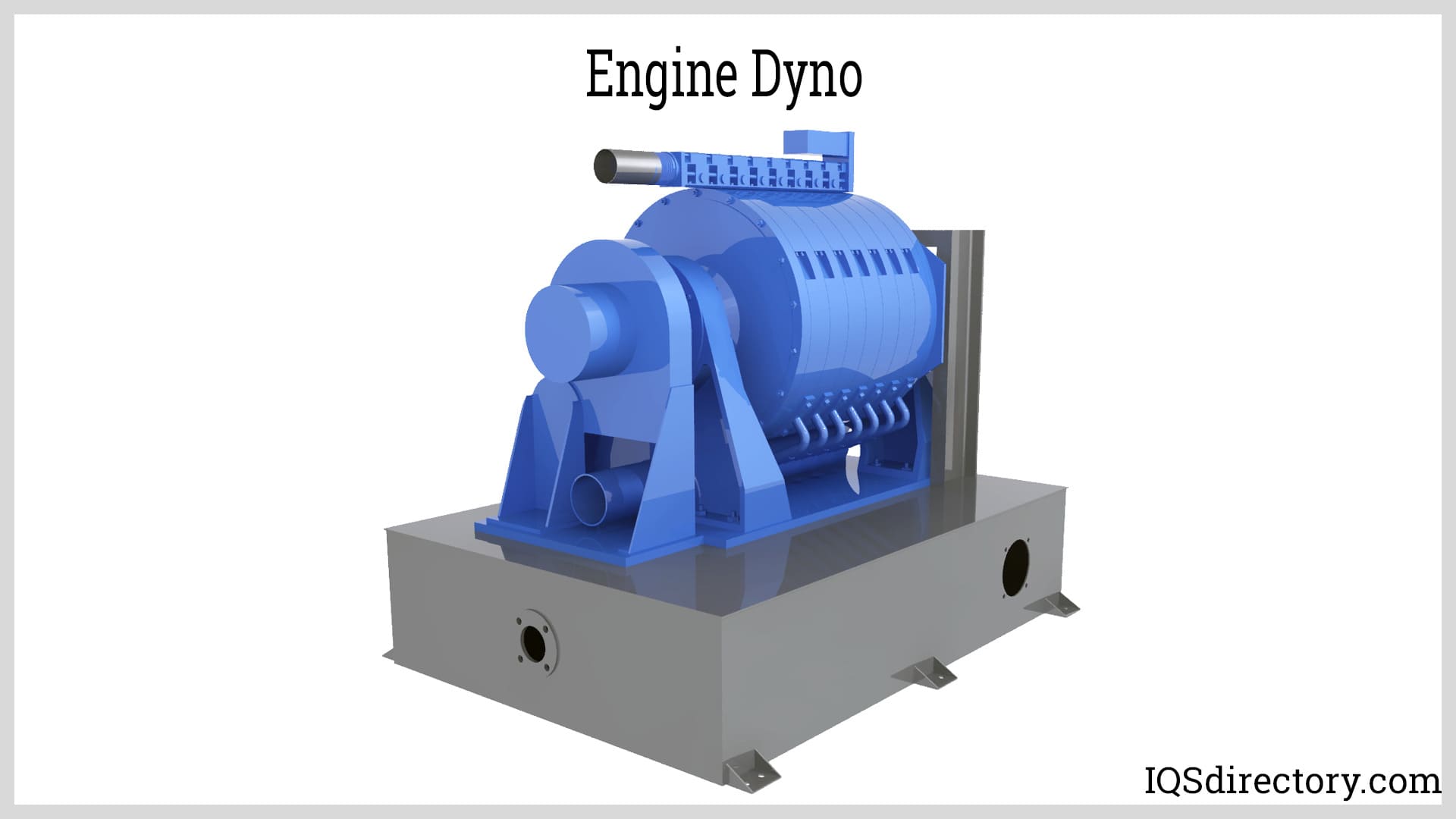

What is an Eddy Current Dynamometer?

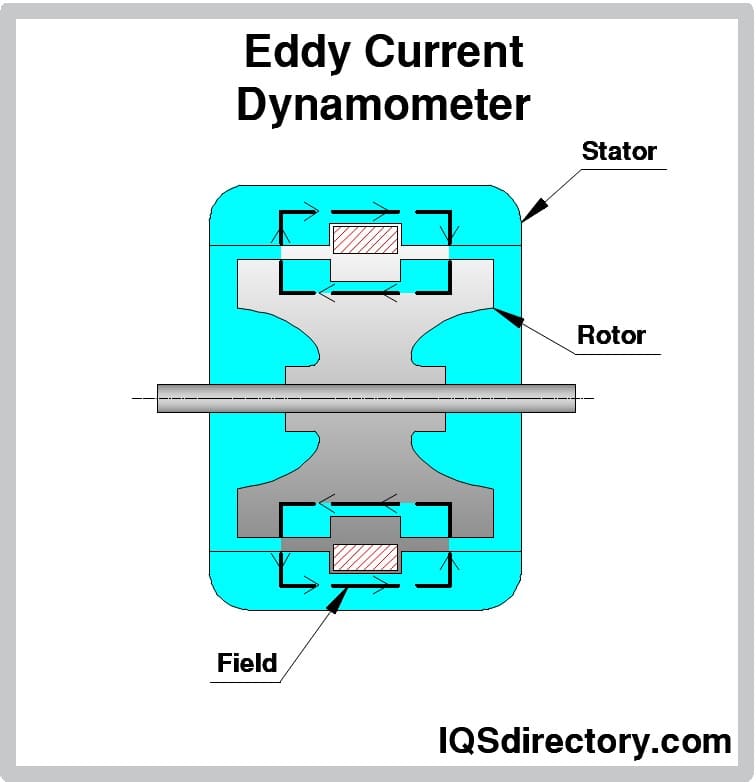

It comprises a stator, which has windings fixed in stator slots. In the instance of high-rated devices, three-phase windings are put in the stator slots.

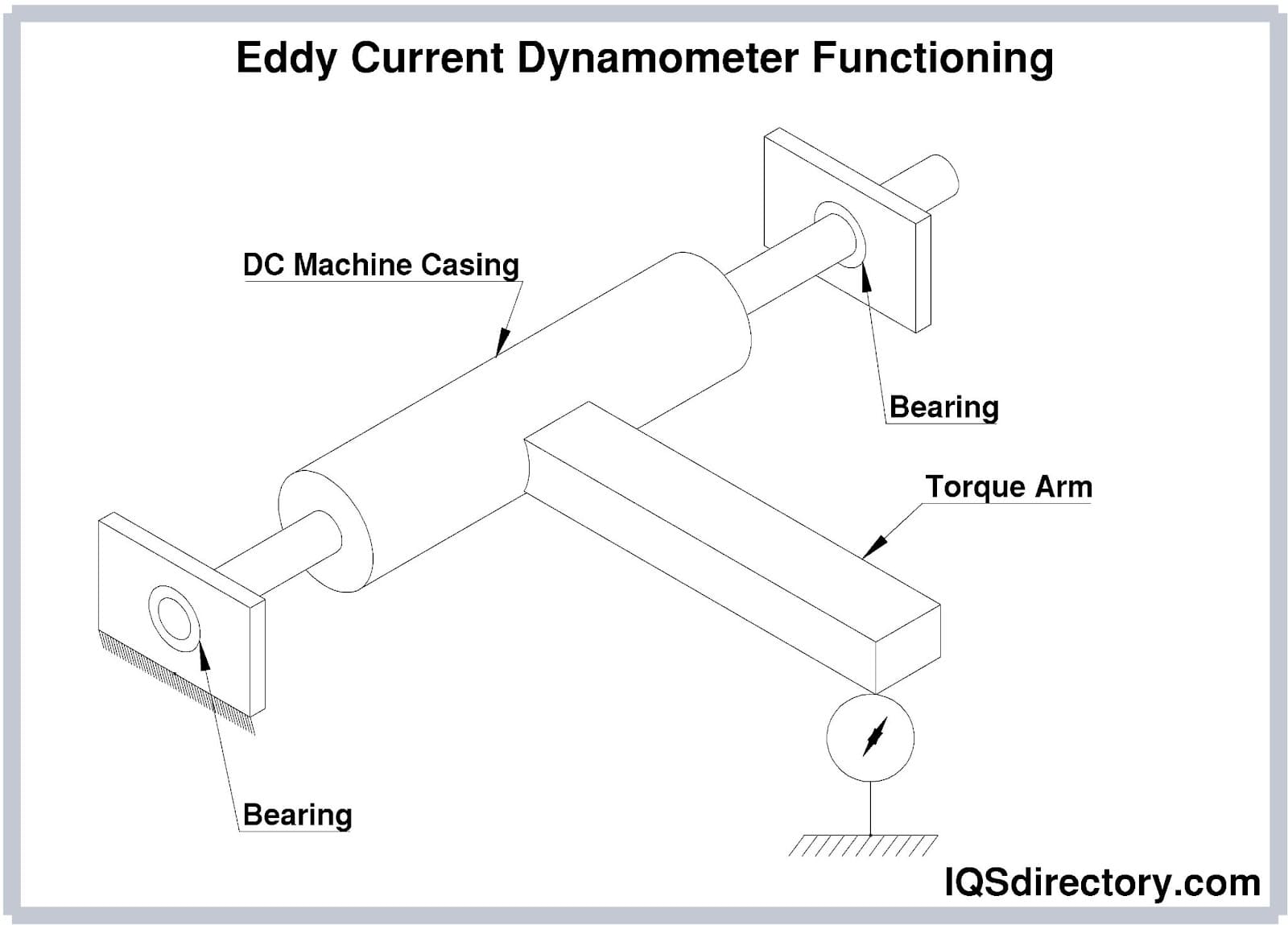

How an Eddy Current Dynamometer Works

As per Faraday’s Law, when there’s a relative displacement between a magnetic field and a set of conductors, an EMF is induced on the conductor set. This EMF is known as a dynamically induced EMF. In the instance of the dynamometer, stator poles are excited by a DC supply connected to the stator.

The stator coils are excited when the DC is supplied; then, a magnetic field is generated in the stator coils. In a three-phase machine, a three-phase spinning magnetic field is obtained in the stator coils if the coils are excited by the three-phase supply. When the prime mover spins the rotor coils, the rotor rotates and co-operates with the stator magnetic field.

It should be noted that the stator magnetic field is stationary. Since the DC is excited, a static magnetic field is obtained. When rotor coils cut the stator's magnetic field, an EMF is induced because in this instance, the magnetic field is stationary and only the conductors are spinning. So there is a comparative displacement between the conductors and the magnetic field.

Typical Specifications of Eddy Current Dynamometers

A few specifications of eddy current dynamometers are below:

- The device must be maintained using clean water without wastage and dirt.

- The cooling water pressure ranges between 0.2Mpa and 0.4Mpa.

- The machine has an outlet for water, and its temperature must be <932 °F (<500 °C).

- It can be used either in the right or left handed direction since it functions both clockwise and anti-clockwise.

- As there are different types of dynamos, it has near accurate torque measurement: about ±4% for the 6kW to 100kW range and ±0.2% for 160kW and above.

- It has a speed precision of ±1 rpm.

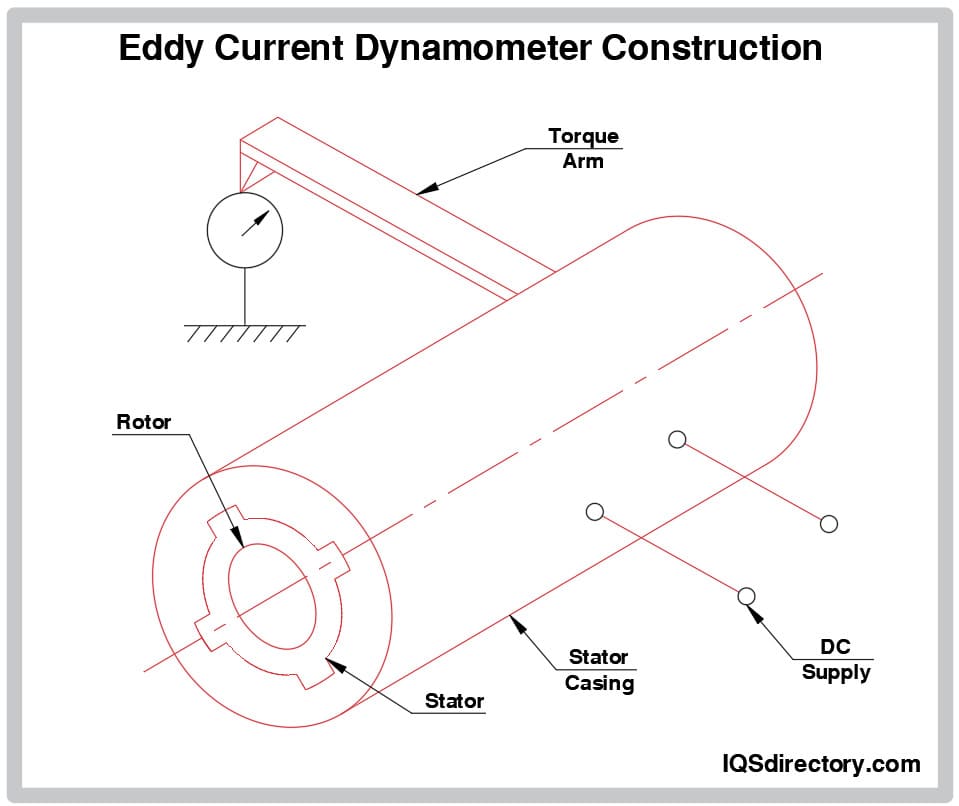

Eddy Current Dynamometer Construction

The dynamometer comprises a non-magnetic steel rotor fixed onto the shaft whose power must be measured. It spins inside a cast iron smooth stator. The space between the rotor and stator is very small. The stator holds an excitable coil, which the DC supply energizes from an external source. The stator is mounted to allow free swinging about the axis. The stator has a torque arm on which a spring is connected.

Features of an Eddy Current Dynamometer

It must be noted that the eddy current dynamometer differs from a typical mechanical dynamometer. The eddy current's direction is opposite to the variation in the magnetic flux and is produced in the rotor.

The rotor opposes the force applied due to magnetic flux, but keeps rotating due to the prime mover input. Since there is no physical contact between the conductors and the magnetic field, the losses generated are very low compared to a normal generator.

Unlike in mechanical dynamometers, an arm is attached to the stator’s body in eddy current dynamometers. A pointer is attached at the arm’s end, which measures the torque generated in the rotor windings. Knowing the rotor speed reveals the amount of power, since the power is equal to the product of the speed and torque.

Applications of an Eddy Current Dynamometer

The main applications are:

- Automobile transmission components

- Gas turbines

- Water turbines

- Internal combustion engine performance testing.

- Utility in small power motors

Advantages of an Eddy Current Dynamometer

The advantages of eddy current dynamometers are:

- Monitors/controls current flow through external control units

- Outstanding brake torque

- Highly stable and precise

- More efficient compared to usual mechanical dynamometers due to reduced loss of friction

- Basic structure

- More convenient than typical dynamometers

- Quicker dynamic reaction because of the low inertia of rotation

- Less copper loss due to the absence of huge windings

Disadvantages of Eddy Current Dynamometer

Below are some of the drawbacks:

- Cannot create torque at zero speed Relatively small, reducing reliability and strength

Choosing the Correct Eddy Current Manufacturer

To ensure you have the most beneficial outcome when purchasing an eddy current dynamometer, it is important to compare several companies using our directory of eddy current dynamometer manufacturers. Each eddy current dynamometer company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each eddy current dynamometer business website using our patented website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple eddy current dynamometer businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services